Simple Steps in Selecting a Mixer

Mixer Application

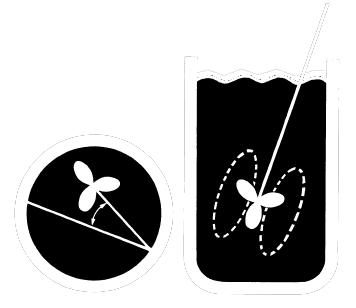

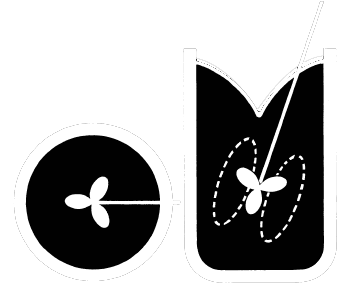

Portable Mixers are used in mixing liquids in drums, totes and tanks with up to 5000-gallon capacity. Mixers are clamped to the side of the tank or external bracket; or screwed through a threaded connection in a drum cover. The mixer is mounted in such a way to allow the propeller to be located approximately 1 1/2 prop diameters from the tank bottom. Shaft length may be lengthened or shortened to achieve this. Optimum mixing will be achieved when the mixer is angled from the tank wall, either off-center (Figure 1) or on-center (Figure 2). Properly mounting a portable mixer will greatly increase mixing efficiency, eliminate vibration and improve mixer service-life.

Mixer Sizing

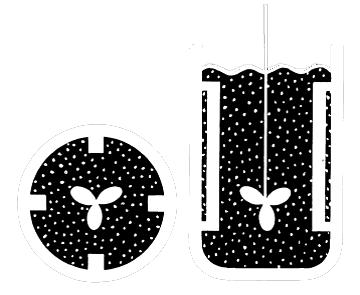

There are extensive studies applied to the physics of mixing. The good news is: we don’t require an in-depth analysis of fluid mechanics. Most common mixer applications focus on blending and solids suspension. For example, one mixer may be sized for a mild blending time. If the materials are mutually soluable, a different motor can be used to produce a shorter blend time or more vigorous blending. Another application requires adequate solids suspension. The mixer is sized based on the percent of solids, and the settling rates of particles in the liquid. Dual propellers may be used. When higher viscosity polymer is being mixed, a gear-driven mixer may be selected.

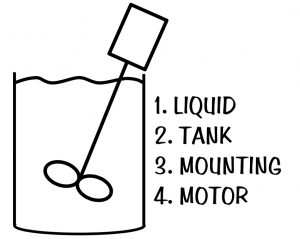

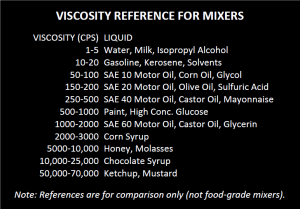

When sizing a portable mixer for your batch processes or continuous use, we need to consider four variables. 1. liquid type, vicosity and chemistry, 2. tank volume and configuration, 3. mounting and 4. motor requirements. Our application guide has more detailed questions. Ask our engineers to review the specifics with you, so that you get the best solution. Custom designs are also available.