Many commercial, industrial and institutional water systems are closed-loop systems. The water is reused for specific purposes. Once water is added to the piping, it is reused, for example, in chilled water or hot water loops. Because the water may become contaminated by the process as it recirculates through the system piping and components, it must be treated. One treatment method uses bypass feeders.

Bypass feeders are economical chemical feed solutions that have been used for decades, yet very little has been written about them. They are called bypass feeders, because they are piped into a secondary loop that runs parallel to a main boiler or cooling water circulation line. Bypass Feeders are used for introducing a predetermined volume of treatment chemicals into chilled water as in air conditioning systems or hot water treatment in heating systems or large engine water jackets. Chemical is introduced into the water stream of a closed, non-evaporative water loop without the use of a pump. Instead, water pressure circulates the chemical dose through the system. These are a type of gravity-feed system.

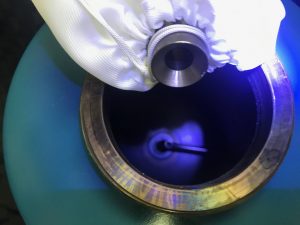

Bypass Feeder Filter Bag

Water treatment specialists use bypass feeders for single or dual-addition feed programs. In the case of cooling towers, the first chemical dose or “slug” gives the initial shock to the system to kill/control biological growth. Follow-up dosage days or weeks later of a second chemical which prevents microorganisms from becoming immune to the first chemical.

Bypass feeders are also know as pot feeders, shot feeders or slug feeders, depending on application, geography or treatment specialist. They are available in many shapes and configurations.

Many feeders come with optional filter bags or cartridges. Filter bags are made of cloth material. They hold up better in high pressures than paper filters which tend to shred. Using a filter bag is a good idea when starting up a newly piped system.

The bag will collect any small particles/metal filings that reside in the system from the installation process. Using a filter bag is also a good idea for existing systems. The filter bag helps to screen out any kind of corrosion particulate that may have built up, or may loosen as the piping is treated. Water treaters may rotate filter bags, starting with a coarse filter for a few days or weeks. When the bag fills up, they may switch to a medium size filter to collect smaller particles. Later they will use a fine filter, to screen out smaller particles as the system has been cleaned up.

A bypass feeder requires a proper flow rate and pressure differential. This can be achieved by plumbing a bypass line across the recirculation pump, or installing a throttling valve in the main line. A flow control valve is recommended to control and maintain the correct flow rate. Another recommendation: do not exceed temperature and pressure maximums.

Bypass Feeder – Cooling Water Treatment

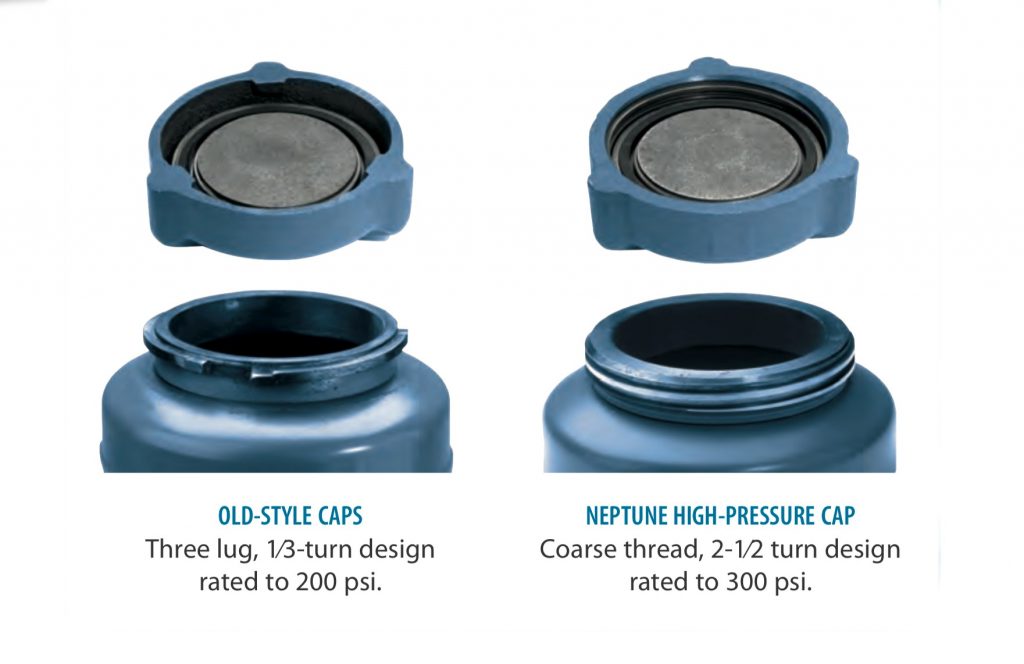

There are thousands of bypass feeders used in chemical treatment for biocide or anti-corrosion addition for closed-loop water systems. They are available in many configurations and volumes and filter options. Since they have a simple, straightforward design many feeders have been in service for over a decade. Note that over time, cap gaskets wear, and should be inspected and replaced. Newer bypass feeders have threaded caps rated for higher pressures than older lug-style cap models on the market. Be sure to consider this when reviewing older installations for possible upgrades.

Older bypass feeders (15+ years) used a three-lug style design (no longer available). The newer threaded cap design allows for a better seal and higher pressure rating. If you have a feeder with the lug cap, consider updating your feeder to one of the newer styles. Also, check gaskets on a regular basis for signs of wear. They are replaceable.