Remember high school chemistry? During your nap, the teacher taught the other students “The concentration of the hydrogen ion is a measure of the acidity or basicity of a solution. We express the concentration of the hydrogen ion in terms of the negative logarithm of the hydrogen ion concentration. This is called the pH of a solution.” Guess what? Operators don’t need to know this to have good pH control! If you have a system that is too complicated, re-think it or replace it. There are more options today than ever before.

What is it? pH is the measure of the activity of Hydrogen ions in the solvent. pH is “power of Hydrogen”.

Pure water has a pH of 7. An acid has a pH less than 7. A base (alkaline) has a pH greater than 7.

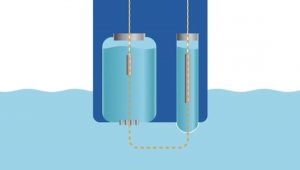

How a pH electrode works. The most common method of measuring pH is a glass potentiometeric pH sensor. This sensor consists of two electrodes – an active and a reference electrode. Both electrodes are made of a metal wire suspended in a stable, neutral electrolyte solution. The reference electrode maintains a steady reference voltage. It completes an electrical circuit with the active pH-sensitive electrode. A small number of ions flow from the reference electrloyte solution through the porous reference junction into the process fluid.

The sensor measures a voltage proportional to the ion concentration of Hydrogen in the water. The glass in the pH electrode attracts Hydrogen ions. The reference electrode is in a neutral pH solution. Between the two electrodes, there is a charge imbalance. That charge imbalance gets measured. Unlike Chlorine analyzers that measure current, pH requires measuring voltage. In a sense, much of the operation of a pH analyzer is that of a voltmeter. (The rest is display and various outputs.)

More details? Okay! The voltage across the active electrode glass changes in response to the concentration of Hydrogen ions in the process around it. When there is a larger number of positively charged Hydrogen ions outside of the electrode than inside, a positive voltage occurs. This means that the process is acidic, less than 7 pH. When there is a smaller number of positively charged Hydrogen ions outside of the electrode than inside, a negative voltage occurs. The process is basic, greater than 7 pH. When the concentration of Hydrogen ions is the same on the outside as inside of the active electrode, the voltage is zero. The process is neutral, 7 pH.

Three components of the pH sensor are designed with specific functions:

- The sensor body is built for chemical compatibility and mounting considerations.

- The glass bulb must be compatible with the process liquid, pH swing, and temperature.

- The reference junction is chosen by size, thickness, and quantity, based on the pH range, temperature, pressure, and aggressiveness of the process.

Sensor selection changes with the application. For plating and wastewater applications, differential pH sensors generally last longer. Old salt-bridge junctions can be replaced.

Pharmaceutical batch processes often require insertion-style sensors that can work at high temperatures for a short period of time.

pH Control & Measurement is used in wastewater neutralization, process control, or drinking-water or waste-water permit compliance sensor selection is key. We provide unique sensors for each of these three types of water: Clean – Dirty – Aggressive Process.

- Clean Water Processes include: filtered water used in pharmaceutical manufacturing, power generation, food production, potable water, reverse osmosis for water filtration, boiler feed water and boiler condensate

- Dirty Water Applications are where sensors can be coated, but the electrode is unharmed. These include municipal and industrial wastewater treatment plants, food manufacturers, and other industrial facilities. The coating may be sticky or a sludge.

- Aggressive Process Water includes parts wasting, plating, metal finishing, chemical production, and refineries. Often, these are hard coatings that crystallize on the sensor.

Here are some questions for pH sensor selection.

- How much chemistry will be added?

- Will the chemistry be monitored, blended, pumped, or a combination of the three (pH control)?

- What does the process look like?

Good pH Control Consists of (1) a sensor that is chemically compatible with the process, (2) a strong output signal, (3) integral cable that uses proper shielding as recommended by the manufacturer, (4) a controller with easy-to-program functions and outputs required to activate a pump or output to a control system, (5) off-the-shelf replacement parts, (6) a reliable blending and chem feed system, (7) people you can talk to who want to make it work right the first time.

pH Maintenance & Calibration

pH Analyzers should be calibrated at least monthly using two of three buffer solutions- pH 7, with 4 or 10. (Every operator does this, right?) When calibrating, note the efficiency/slope of the probe. Hopefully, it remains above 90%. If the efficiency drops below 90% there are three possible causes:

- The electrode is dirty and needs cleaning. In most cases, a soaking in vinegar for a few hours does the job. If there is a build-up, then, brushing the electrode with a soft brush should precede the soaking. If the build-up is from a biofilm, an oxidizing solution, such as bleach, will clean it up.

- The reference solution needs to be replaced. It costs only pennies for fresh reference solution – a good reason to replace it at each calibration.

- Buffer solution is old or expired. Buffer solution that has been left open for more than a month is past its “expiration date.”

A simple pH loop is easier to install, maintain and troubleshoot.

Now that’s something we can understand! Want to hear more of the story?

Contact: Murphy & Dickey, 630-655-1080.