[vc_row][vc_column][vc_column_text css=”.vc_custom_1598973657614{margin-bottom: 0px !important;}”]For years, thousands of facilities have implemented the recovery and reuse of boiler water. It saves water and the energy it takes to reheat the water. It also saves money. To be reused, recirculated boiler condensate water must be treated in various ways. This ensures the quality of the water, and the effect it will have on the piping, feed equipment and boiler itself.

Neutralizing Amine Feed

The most common of condensate treatments is amine feed. Neutralizing amines – those which lower pH – are used in boiler water treatment to control corrosion in condensate return lines.

This is one of the most asked about and often misunderstood applications for pH control in the chemical feed.

Neutralizing amines are used in boiler water treatment to control condensate return line corrosion. Here’s why:

- They are alkaline, which means they can neutralize acids that can form in the condensate by raising the pH.

- They reduce the effects of carbon dioxide and other acid-forming compounds.

- They do not have any adverse effects on copper or copper alloys under normal treatment conditions, as long as pH is consistent. Regulating amine feed between 8.8-9.2 pH range in a mixed copper-iron condensate system is an example of this.

There are two approaches to measuring pH here. Both methods work. Both have benefits.

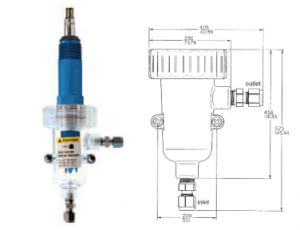

The first is to install the pH sensor into the hot process line. The system requires a pH controller, sensor, mounting hardware, amine feed pump, injection quill.

The second approach is to run a bypass line through a sample cooler to a low-temperature pH sensor that has been installed in a low flow cell. This is the better approach for sensor longevity, as prolonged exposure to high temperatures will shorten the life of any pH sensor. The system requires a pH controller, sensor, low-flow mounting hardware, amine feed pump, injection quill, and a sample cooler.

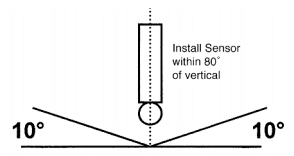

Note: To ensure correct measurement, pH sensors should be mounted vertically or at least 10° from horizontal.

We offer a pH controller from Rosemount that can accept either of the two sensor options for this application. Also, we offer a diaphragm metering pump from Neptune that can accept a 4-20 mA input signal and vary the feed rate of the amine solution into the system.[/vc_column_text][/vc_column][/vc_row]