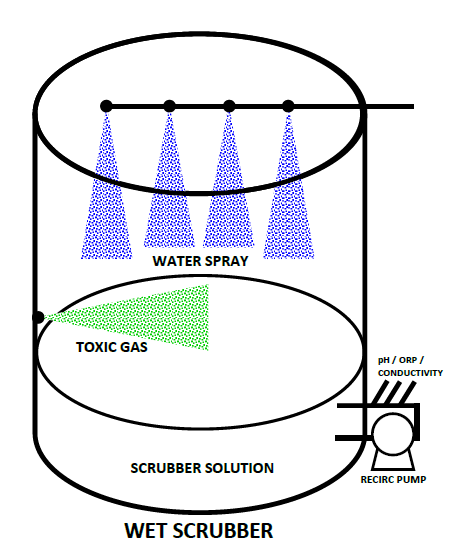

A common wet scrubber design consists of a large tank into which toxic gases are fed. Inside the tank are water spray nozzles. As the gas passes through the water mist, acids are absorbed, allowing clean air to rise. In time the rinse water will become saturated and must be replaced.

Wet Acid Scrubber – Controlling Caustic Feed

pH & conductivity instrumentation is used to measure the quality of the water. The ideal location for the water quality sensors in the recirculating line on the sump of the wet scrubber. Mount the sensors in flow-through tees. Try to use at least a 2” or 2.5” diameter tee, so that the entire lower two inches of sensor is immersed in solution. The glass bulb, junction, and stainless steel grounding band need to be in solution. (See circled area in photo.)

pH Measurement

pH controllers are used in scrubbers where continual blowdown and replenishment is required. They control addition of basic gas-scrubbing chemicals, such as caustic (NaOH) or lime (CaO). pH sensors can be used in lower caustic concentrations with minimal effects from the buildup of by-products in the scrubber solution. However, using a strong caustic solution (10–15 % NaOH) greater than 14 pH can destroy a sensor’s glass electrode.

ORP Measurement

ORP (Oxidation-Reduction Potential) may also be used along with a pH measurement, if the scrubbing reaction involves an oxidation and reduction reaction. ORP measurement is limited to indicating the complete exhaustion of a particular chemical. It is not a good indication of concentration.

Here are the recommended Rosemount Sensors for Wet Acid Scrubbers (mounted in recirculating line) pH & ORP: Model 3500P (or 3500 VP, as VP connection may be useful for mounting in a flow-through tee.) A sensor version that uses a pre-amp will generate a stronger output signal to the controller.

Conductivity Measurement

A Rosemount Model 228 Toroidal Conductivity Sensor may also be helpful. As more caustic (KOH or NaOH) is added to neutralize the acid, the amount of salts (KCL or NaCl) generated in the scrubber will increase. As the solution’s conductivity increases, the system will be less effective at “absorbing and neutralizing” acids. A conductivity controller will signal the system or operator to dump some of the water in the wet scrubber sump and add fresh, clean water.