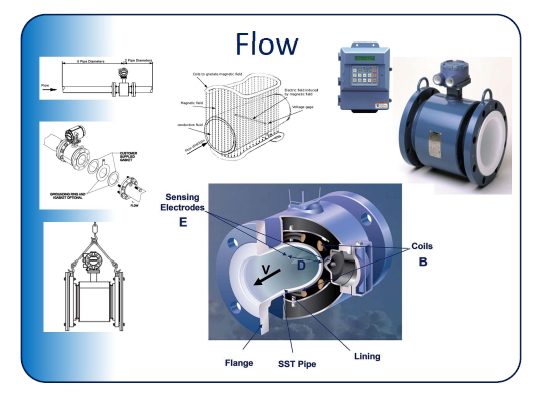

How Do They Measure Flow?

When liquids flow through an electromagnetic flowmeter, they produce a measurable voltage that is proportional to the flow rate. In simple terms, the voltage is proportional to the magnetic field strength, along with the velocity and length of the conductor – in this case, water or process liquids.

Magmeters have two main parts: a transmitter and a flow sensor. The flow tube consists of an inner tube, wrapped in an electrical coil, all within an outer protective tube. When a voltage is applied, these coils produce a magnetic field around the inner tube. As electrically conductive fluids flow through the flow tube, electrodes measure the voltage. The transmitter converts this signal into a flow display and output to other devices.

Magmeters require proper grounding. Grounding ensures a good measurement because the magnetic field in the flow tube remains isolated from magnetic noise from nearby electrical equipment.

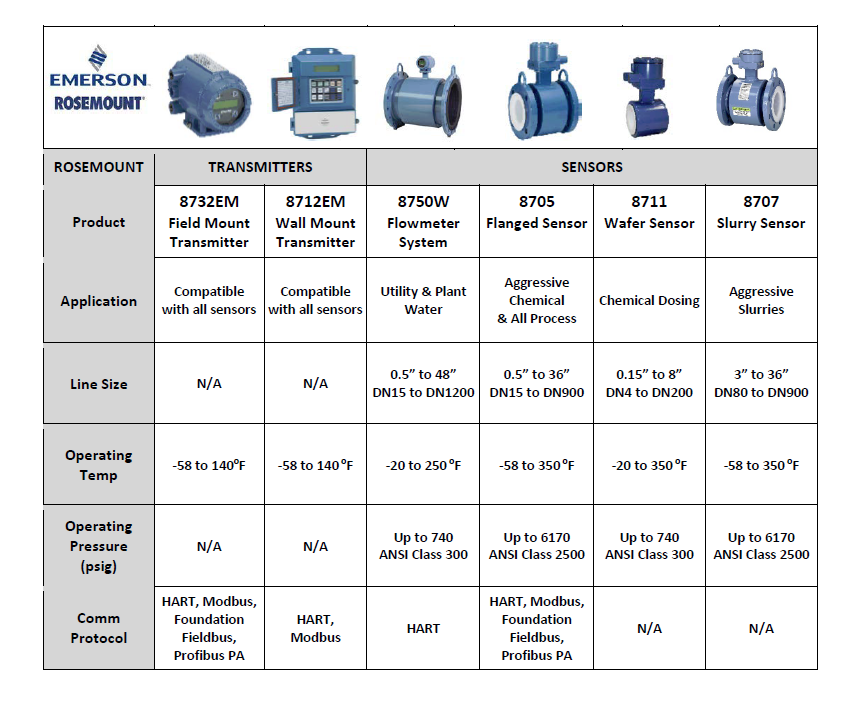

Rosemount offers a selection of magmeter transmitters and flow sensors for both industrial and municipal applications.

SMART Meter Verification is a tool designed to ensure flow accuracy. It continually monitors meter health, alerting at the first sign of trouble. Flowmeter verification can be done without process shutdown or removal of the sensor. A manually initiated diagnostic test that reviews the transmitter’s and sensor’s critical parameters. A verification document of calibration can be generated. This video demonstrates flowmeter verification: